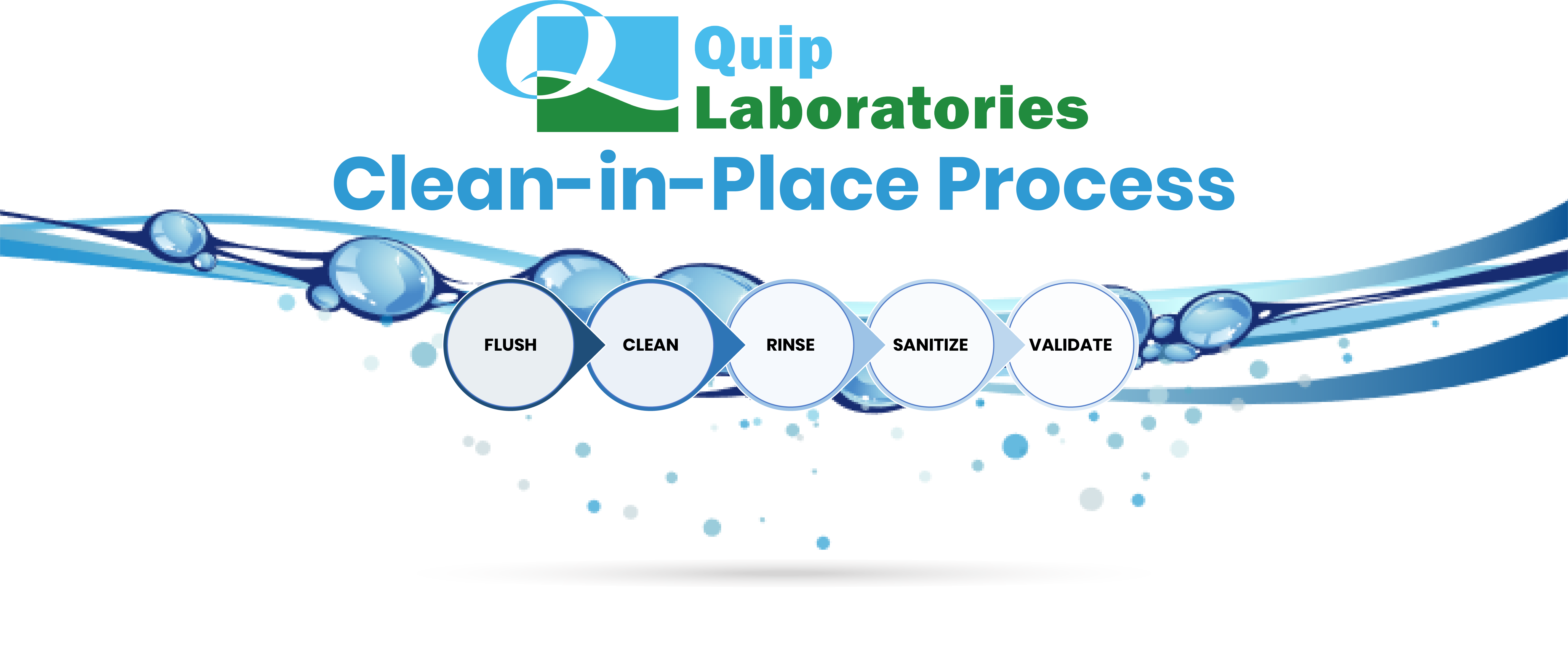

Step 1: Pre-rinse

Pre-rinsing dissolves some surface sugars and fats, flushes the system, and allows our Biosafety Account Managers to check for, and where possible, eliminate leaks or water loss.

We recommend using de-ionized water, water that has been processed through reverse osmosis, or re-use the final rinse solution from the previous cleaning sequence. A Turbidity Sensor may be used to verify that the pre-rinse has effectively removes solid soil build up.